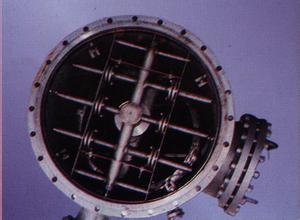

Spray-Nozzle Distributor

T.C.I spray type distributor realise a homogeneous

distribution of liquid by using fully conical nozzles.

An advantage of this spray nozzles is that it his insensitive

to horizontal adjustment, which is advantages for large column

diameters. Furthermore liquids containing solid particles can be

distributed without plugging problems to the nozzles. In the present

case of high gas capacity factor the liquid should be distributed

using a low pressure difference to neglect remixing effects at the distributor.

Pressure feed distributors can be categorized as either ladder arm type or spray nozzle type distributors.

These distributors are used for very specific applications, such as, heat transfer services.

Because these distributors operate under pressure, the orifice sizes in these distributors are usually small.

Pressure feed distributors should not be used with flashing feeds. The major advantage of using a

pressure feed distributor is total wetting of the surface of the packed bed. High point to point flow

variation and high cost are some of the disadvantages to these types of distributors.

| ITEM/SIZE |

LIQUID LOAD |

RECOMMENDED |

| |

M3/HR |

COLUMN DIAMETER IN MM |

| PAN TYPE DISTRIBUTOR |

0.2-225 |

90-1750 |

| DECK TYPE DISTRIBUTOR |

3-225 |

>180 |

| TROUGH TYPE DISTRIBUTOR |

0.2-65 |

>580 |

| LADDER TYPE DISTRIBUTOR |

2-110 |

ALL |

| SPRAY NOZZEL TYPE DISTRIBUTOR |

2-220 |

ALL |

|