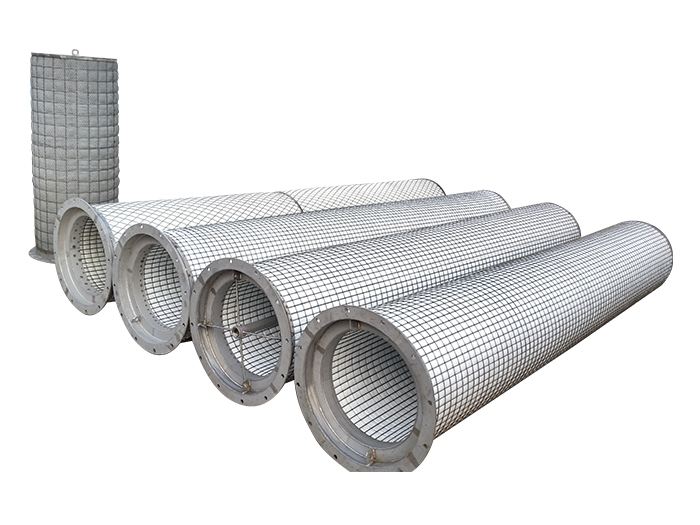

Fiber Glass Wool Fiber Bed Mist Eliminator for Demisting

Fiber bed mist eliminator

· Acid or alkaline mist can cause the problems of corrupt the vessels, product impure, heat exchanger blocked, catalyst failure, instrumentation damage. When it is released into the atmosphere would cause environmental pollution.

There is a wide range of fibre materials available (Glass, Carbon, Polypropylene, Polyester, P.T.F.E.) and in the case of Glass there are many options of fibre diameters + fibre bed density specifications to select from to achieve different efficiency / pressure loss / housing space requirements. Broadly, there are high efficiency Brownian Diffusion types, high velocity Impaction types, and some in between. See the Tables below for these fibre bed and installation style options. (Note – High velocity types can only be installed in (F) Style Standing orientations.)

3. Numbers of the holes= 24

4. The diameter of the holes= 11 mm

5. The diameter of SARAN cloth= 940 mm

Mist eliminators usually include electrostatic mist eliminator, wire mesh mist eliminator and fiber mist eliminator. Wire mesh demister is efficiency investment, compact, easy to install, in the chemical production plant application is very common, but cannot eliminator the mist diameter is larger than 3μm. Electrostatic mist eliminator can eliminator different diameters’ mist, but its disadvantage is high investment costs, high operating costs, its application has been limited.

Fiber mist eliminator demister is designed to remove a variety of mist particles in the air flow device, not only can remove large particle gas stream mist particles (diameter> 3μm), but also for removing submicron also very effective.

Applications for Fiber mist eliminator

|

Devices

|

Usage

|

Solutions

|

|

Sulphuric Acid

|

Intermediate absorber tower eventually dry absorber oleum storage

|

Mist destruction catalyst mist corrosion damage downstream equipment catalyst corrosion of downstream equipment pollution

|

|

Chlorine

|

Wet Dry chlorine hydrogen chlorine

|

Saline mist increase the drying tower in an amount of sulfuric acid mist corrosion of the compressor, reduce the purity of the hydrogen product salts and other particles reduce the purity of the product

|

|

Nitric acid

|

Ammonium platinum supply system air supply system recovery

|

Iron and mist pollution platinum platinum mesh mist under normal operating loss of nitric acid corrosion of downstream equipment

|

|

Ammonium Nitrate

|

Neutralizer

Evaporator

|

Ammonium nitrate with exhaust discharge loss of product or environmental pollution ammonium bad smog forming emissions

|

|

Urea

|

Evaporator

Granulator

|

Product loss or bad environmental pollution urea visible smoke

|

|

Sulfonation

|

Before the reactor, the reactor after

|

Mist caused by impure product mist cause air pollution

|

|

Phosphoric acid

|

Heat absorption

|

Mist causing air pollution

|

|

Compressed air

|

After the condenser

|

Oil mist and equipment corrosion caused by impure product

|

|