|

|

|

| |

|

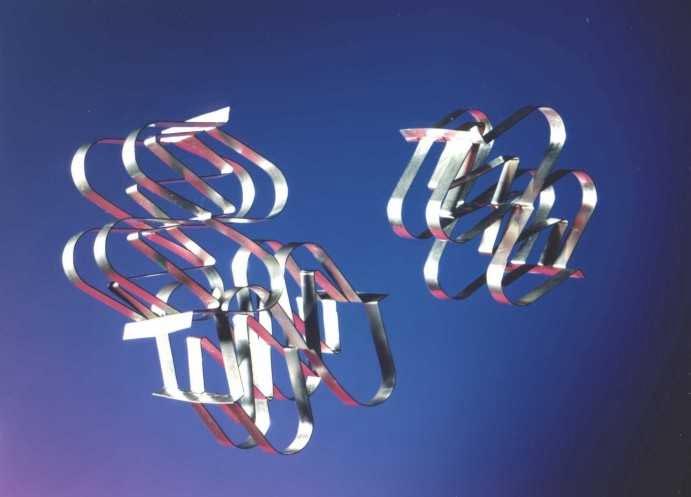

"Raschig Super-Ring®" which sets new performance standards in the use of mass transfer columns. The Raschig Super-Ring® optimized fluid-dynamic design produces an effective mass transfer between the phases flowing in the column. It achieves large interfaces and an even distribution of the liquids over the column cross-section. High loading capacities permit large column throughputs, and low pressure drops yield low operating costs.

Features

- Liquid film flow with entangled packing, similar to our latest model SPIRAX, resulting in large material transfer (Same effect is confirmed with our product, TELLERETTE.)

- Flooding at joints prevented with “Semi Structured Packing”

- Support rings do not have to be completely removed when remodeling shelf block towers

- However, when remodeling to standard packings, support rings need to be completely removed up to the outer-circumference edge.

- Reduced number of redistributors with homogeneous liquid distribution

- Cost savings with high-speed machines

- RSR is available in SUS as well as materials that are thick or thin such as titan, nickel, and tantalum

- HETP, pressure loss and intensity are far beyond the most efficient random packings

- Verified high performance of RSR by tests in the world-class distillation research institute, FRI (Fractionation Research, Inc.)

Major Applications

- Absorption, diffusion and distillation towers

Specification of Raschig Super-Ring (RSR)

Raschig Super-Ring

(model number) |

Weight (kg/m3) |

Bulk Quantity

(number/m3) |

Surface Area

(m2/m3) |

Void (%) |

Size (Diameter) |

| [mm] |

[inch] |

| RSRNo.0.3 |

340 |

180,000 |

315 |

96 |

15 |

0.3 |

| RSRNo.0.5 |

275 |

145,000 |

250 |

97 |

20 |

0.5 |

| RSRNo.0.7 |

250 |

45,500 |

180 |

98 |

25 |

0.7 |

| RSRNo.1 |

220 |

32,000 |

150 |

98 |

30 |

1 |

| RSRNo.1.5 |

190 |

13,100 |

120 |

98 |

38 |

1.5 |

| RSRNo.2 |

165 |

9,500 |

100 |

98 |

50 |

2 |

| RSRNo.3 |

150 |

4,300 |

80 |

98 |

70 |

3 |

|

|

| New Product |

|

Polypropylene Tellerette 3K

ETFE +25% Glass Tri packs 2inch

|

| |

|

|

|

|

| |

|