|

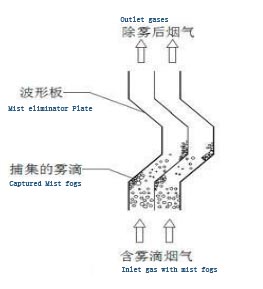

Vane-type mist eliminator

1. MIST ELIMINATOR (VANE/BAFFLED TYPE)

The vane-type mist eliminator consists of a series of baffles or plates, and the gas flows between them. The droplet that is impinged on the surface has a free fall downward. The space between the baffles varies from as low as 5 to 75 mm, and the depth in the direction of the flow varies between 150 and 300 mm.

In case of a horizontal separator, a significantly higher gas flow can be achieved in comparison to the vertical gas flow, simply because, in the horizontal mode, the liquid can easily drain downward due to gravity. This is the reason why the vane-type mist eliminator is very popular in horizontal separators.

2. Features

1. It can separate and remove a lot of dust or viscous mist from a fluid without stoppage. It is suitable for the separation of quite rough mist.

2. Resistance loss is small and pressure drop can be made small even at high gas velocity. Horizontal type: 5-7 M/S Vertical type: 4-6 M/S

3. The installation area is small and the installation cost is economical even for the treatment of large quantity of gases.

4. It is possible to choose a heat-resistant and corrosion-resistant material, depending on the gas conditions, and FRP, PP, PVC,ABS, SS304, SS316L are available.

3. Purposes

Removal of harmful materials in gases (prevention of air pollution)

Removal of impurities in gases (improvement in the purity of products)

Prevention of scattering of raw material products (cost reduction)

Installed for the plant pre- and post-process (lengthening the lifetime of a plant and saving energy); Separation and collection of mist

4. Applications

SCRUBBERS, EVAPORATORS, KNOCKOUT DRUMS. VACUUM TOWER, INSTALLATION, AIR WASHER, AIR HANDLING UNIT.

|