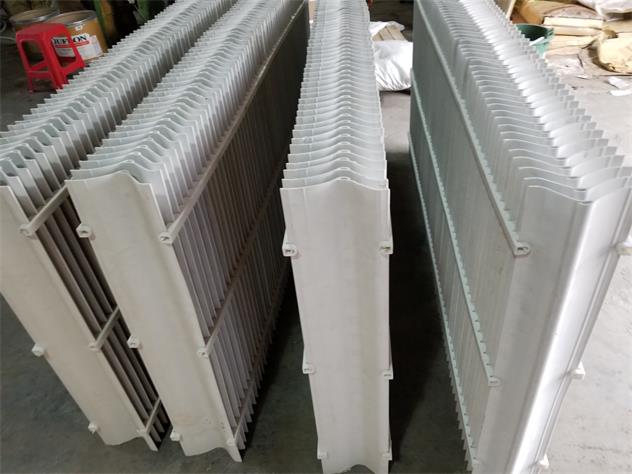

PP VANE TYPE DEMISTER MIST ELIMINATOR

Demister (mist eliminator) is mainly composed of fixtures waveform blades, sheet, strip cards, etc., in the wet FGD, absorber during operation, easy to produce a particle size of 10 - 60 micron "fog" "Fog" is not only contains water, it dissolved sulfate, sulfate, SO2, etc., but also caused the fan, heat exchanger and flue tarnished and severe corrosion, so the wet desulfurization process of absorbing device made defogging requirements, the purified gas leaving the absorption column prior to defog.

Brief introduction

Defogger system by demister body and flush system. Specifically two demister body wash water pipes, nozzles, supports, support beams and associated connections, fixed, seals and other components

Usage of Demister (mist eliminator)

Defogger for the separation of gas entrained droplets tower to ensure that there is mass transfer efficiency, reduce the loss of valuable materials and improving the operation of the compressor after the tower, and more generally set defogger overhead. Can effectively remove 3--5um droplets, between trays If set demister, not only to ensure the efficiency of mass transfer trays can also reduce the plate spacing. So defogger is mainly used for gas-liquid separation. Also for the air filter is used for gas separation. In addition, the screen can also be used as instruments of various types of industrial instrumentation buffer to prevent radio interference in electronic jammers and the like.

Wet FGD, absorber during operation, easy to produce a particle size of 10 - 60 micron "fog", "fog" not only contains water, it dissolved sulfate, sulfate, SO2, etc. If not properly resolved, any incoming chimney "fog"

(Three-dimensional simulation desulfurization system diagram)

Is actually the SO2 emitted into the atmosphere, but also caused the fan, heat exchanger and flue tarnished and severe corrosion. Therefore, the absorption of the wet FGD process equipment made defogging request was purified gas before leaving the absorber should demisting. Defogger FGD system is the key equipment, and its performance directly affects the wet FGD system can run continuously and reliably. Defogger failure will not only cause outage desulfurization system, and may even cause the entire unit (system shutdown).

The most common arrangement in the form of mist eliminators are flat-roof style layout and arrangement.

|