|

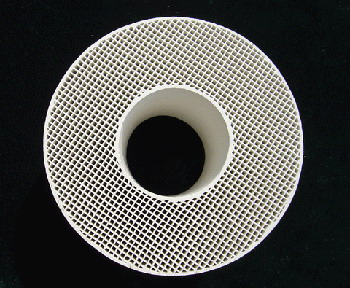

Thermal Store Honeycomb Ceramic

The thermal store honeycomb ceramic a new-type combustion Tec with enormous energy-conservation and environmental protection that High Temperature Air Combustion (HTAC). The thermal store honeycomb ceramic is used extensively in the various field, such as the steel, machinery, building materials, petrochemical industry, colored metal etc, as the key part of HRC, such as different kinds of heating furnaces, hot-blast furnace, heat-treatment furnace, cracked stove, roaster, melting furnace, hot stove, oil gas boiler, etc. This Thermal Store Honeycomb Ceramic technology is to make two regenerator to absorb heat and send out heat alternatively through the direction change device, recuperate the heat of the exhaust gas to the maximum extent, and then heat the combustion-supporting air and coal gas to more than 1000℃, even the inferior fuel (e.g. the blast furnace gas ) of lower calorific power can also catch fire steadily and burns high-efficiently. It can save 40-70% of fuel, improves output more than 15%, decreased more than 40% that billet steel is oxidized and burnt, NOx tap smaller than 100ppm, and make the temperature of exhaust gas emission lower than 160℃. It will reduce the greenhouse effects of the earth greatly. If the Thermal Store Honeycomb Ceramic HTAC technology is adopted by most industry stove kilns of the whole country, its economic benefits and social benefit are inestimable. Thermal Store Honeycomb Ceramic will alleviate the state of the energy in short supply greatly and improve the human living environment effectively.

|

Product Name

Performance Index

|

Low Temperature Thermal Store Honeycomb Ceramic

|

High Temperature Thermal Store Honeycomb Ceramic

|

Thermal Store Honeycomb Ceramic Fender

|

|

Material

|

Cordierite/Mullite

|

Alundum/Mullite |

Electro –Melting Alundum

|

Altitude Aluminium

|

|

M70

|

M60

|

|

Chemical Composition

(%)

|

Al2O3

|

34.5±1.0

|

70±1.0

|

60±1.0

|

85±1.0

|

56~60

|

|

SiO2

|

49.7±1.5

|

29±1.0

|

38±1.0

|

13±1.0

|

30~35

|

|

MgO

|

13.5±1.5

|

Modicum

|

Modicum

|

Modicum

|

Modicum

|

|

Other

|

<2.0

|

<2.0

|

<3.0

|

<4.0

|

<8.0

|

| W/v(g/cm3) |

0.70~0.85

|

1.00~1.15

|

0.95~1.05

|

1.65~1.95

|

1.20~1.55

|

|

Coefficient of Thermal Expansion (×10-6/℃)

|

2.0~3.0

|

4.5~5.2

|

4.2~5.0

|

6.5~7.5

|

7.0~8.0

|

|

Thermal Conductivity(W/m.k)

|

≥1.1

|

≥1.0

|

≥1.0

|

≥1.0

|

≥1.0

|

|

Highest Working Temperature(℃)

|

1350

|

1600

|

1550

|

1600

|

1500

|

|

Normal Temperature Compressive Strength (MPa)

|

A axis >23.0

|

>26.0

|

>23.0

|

>25.0

|

>20.0

|

|

B axis >5.5

|

>10.5

|

>9.0

|

>5.5

|

>5.5

|

|

Common size (mm)

|

100×100×100,100×100×150,150×150×100,150×100×100、(Wall thickness):0.5、0.7、1.0、2.0 (Aperture):2.5×2.5、3.0×3.0、5.0×5.0

|

We also can design and produce according to customer’s specific requirements

|

|