|

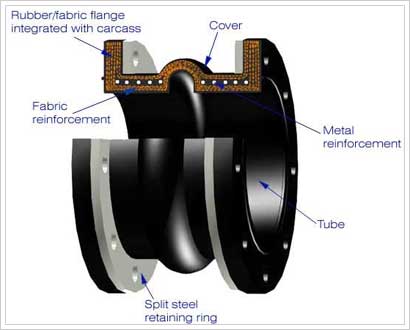

Spool type rubber expansion joint

As a standard construction, Spool type rubber expansion joint Type 10 and 20W are made of high tensile fabric and synthetic rubber reinforced with spring steel wire and/or metal body ring. The full face flanges are integral with joint carcass.

This type of Spool type rubber expansion joint faced flanges are of a sufficient thickness to form a tight seal against the mating metal flanges without the use of gaskets. Additionally, Type 10 and 20W feature molded 'O-RING' on each flange face for quicker sealing with less torque. Only arch configuration and minimum face to face length differ.

Performance of Spool type rubber expansion joint

In a performance of rubber joint, temperature, pressure, and movement may be the most critical factor. The durability of the various rubber grades depends on the type of medium being conveyed, its temperature, external environment, flow velocity, period of exposure and a number of factors.

Resistance to pressure is dependent on dimensions, design, temperature conditions and movement required.

Resistance to vacuum depends on joint stiffness and arch profile. Full vacuum containment is done best with narrow straight wall arch design.

For higher pressure and vacuum rating, exclusively designed metal reinforcing rings and multi layered hard drawn steel wires are bonded between the tube and cover.

Pressure rating of Spool type rubber expansion joint

|

Nominal Diameter (mm)

|

Type 10L & 20WL

|

Type 10 & 20w

|

Type 10H & 20WH

|

|

Pressure

(bar)

|

Vacuum

(mm Hg)

|

Pressure

(bar)

|

Vacuum

(mm Hg)

|

Pressure

(bar)

|

Vacuum

(mm Hg)

|

|

25~ 300

|

10.5

|

660

|

13.0

|

760

|

20.0

|

760

|

|

350~ 500

|

4.5

|

660

|

8.0

|

760

|

15.0

|

760

|

|

550~ 600

|

4.5

|

660

|

7.0

|

760

|

12.0

|

760

|

|

650~1000

|

3.5

|

660

|

6.5

|

760

|

10.5

|

760

|

|

1050~1650

|

3.5

|

660

|

5.5

|

760

|

10.0

|

760

|

|

1700~2000

|

3.0

|

660

|

5.0

|

760

|

8.5

|

760

|

For higher pressure expansion joint,

VACUUM CONTAINMENT

expansion joints, Type 10 and 20W are designed for maximum working pressure and full vacuum rating given above. They are capable of withstanding line vacuum as the joint carcass and arch are reinforced by hard drawn spring wire and special support ring.

NOTES :

Vacuum rating is based on installed length without external load.

Movement capability

|

Type

|

Normal Diameter

(mm)

|

Max. Movement(mm)

|

|

Axial

|

Lat.

|

|

Comp.

|

Ext.

|

|

10 & 10L

|

25~150

|

12

|

6

|

12

|

|

200~450

|

19

|

9

|

12

|

|

500~600

|

22

|

11

|

12

|

|

650~1000

|

25

|

12

|

12

|

|

1050~1800

|

28

|

14

|

12

|

|

20W & 20WL

|

25~40

|

20

|

10

|

12

|

|

50~100

|

35

|

17

|

16

|

|

125~250

|

40

|

20

|

18

|

|

300~500

|

40

|

20

|

20

|

|

550~1000

|

50

|

25

|

23

|

|

1050~1800

|

60

|

30

|

28

|

|