|

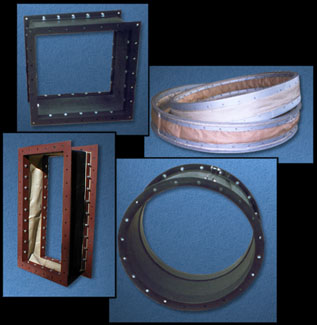

Fabric Duct Expansion Joints

Uses:

Fabric expansion joints are used in place of metal expansion joints to resolve problems with thermal and mechanical stress inherent in some metal expansion joints. They are for use on on Boiler Ducts, Air Preheater Ducts, Precipitator Ducts, Scrubber Ducts, Kilns and Fan Ducts. Principal industrial users of fabric expansion joints are Power Generation plants, Paper and Pulp Mills, Steel Mills, Refineries, Cement Plants and Incineration Plants.

Fabric expansion joints offer a greater ability to handle axial, lateral, torsional and angular movements. They also offer superior corrosion resistance and drastically extend the life of the expansion joint.

There are two types of fabric expansion joints:

1. The Elastromeric type which is essentially a rubber type joint consisting of one or more plies of reinforcement laminated with the elastomer and vulcanized into a solid product. This type of joint is designed for operating temperatures of 400° or below. The thickness of the joint and the number of reinforcing plies can vary depending on requirements, although most joints are ¼" thick with two ply fiberglass reinforcement.

Service conditions determine the type of material(s) to be used:

- Fluoroelastomers (Dupont Viton or 3M Fluorel) are high performance elastomers that have good resistance to high temperatures, to chemicals and to abrasion, including flue gas and fly ash.

- EPDM is a relatively low cost polymer with high tensile strength and good elongation and flexing capabilities.

- Polymers such as Chlorobutyl, Hypalon and Neoprene are also commonly used in expansion joint construction where high chemical attach, abrasion and temperatures are not present

2. The Composite Type expansion joint is a layered joint consisting of various plies of materials which are overlayerd, bonded, sewn or fastened together. This variety operates in continuous temperature ranges over 400°F. The composite expansion joints materials are various layers of TFE (Teflon), fiberglass fabric, TFE impregnated fiberglass fabric, fiberglass insulation, Butyl, EPDM or Viton/Fluorel fabric. There are other materials that are also employed where special service requirements and ultra high temperatures are present.

Specifications:

Fabric and thickness conform to service requirements. Available with mounting hardware angle flanges, back-up bars and fasteners.

Additional Options:

This type of expansion joint can be factory assembled or shipped knockdown for easy on-site installation. They can be either factory spliced or open ended for field splicing.

|