|

Low Torque AV Gaskets

Standard Features

• EPDM – durometer A, hardness 65 - 68

• PTFE or PVDF-bonded EPDM for maximum

corrosion resistance

• Perfect sealing at low bolt tightening torque

ratings, longer gasket life

• Ideal for plastic piping systems, as well as metal

or plastic-lined metal systems

• Working temperature:

1) EPDM: - 40 – 195º F

2) PTFE-bonded: - 40 – 250º F

3) PVDF-bonded: - 40 – 250º F

• Approx. a 1/3 bolt tightening torque rating as

compared with flat or envelope type gasket.

• Thickness of bonded materials

PTFE: All Sizes: 0.016" (0.4mm)

PVDF: Sizes 1/2" - 2": 0.016" (0.4mm)

PVDF: Sizes 3" - 10": 0.020" (0.5mm)

• PTFE-bonded gasket excellent for most

corrosive chemicals.

• PVDF-bonded gasket is ideal for the following:

1] Semi-conductor industry, because of its purity

2] Aggressive chemicals (strong acids,

bases, halogens, etc.)

3] Media that generates any volatile gas (PVDF

gas permeation is only 1/50 of PTFE)

• Both the PTFE and PVDF-bonded gaskets

employ a proprietary laminating process for

bonding to EPDM, providing the greater

elasticity required for lower sealing torques.

Low Torque AV Gaskets

Materials/Sizes:

Sample Specification

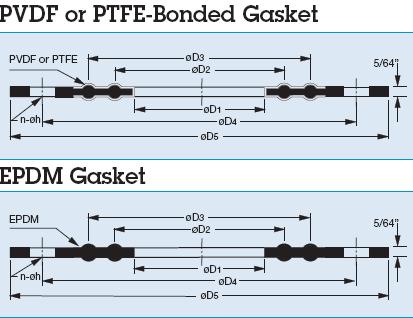

All AV Gaskets shall be of low torque, full face to ANSI

B16.5 dimensions and shall have two concentric,

convex, molded rings between center hole and bolt hole

circle in EPDM, PTFE-bonded EPDM or PVDF-bonded

EPDM, as manufactured by Asahi/America, Inc. |