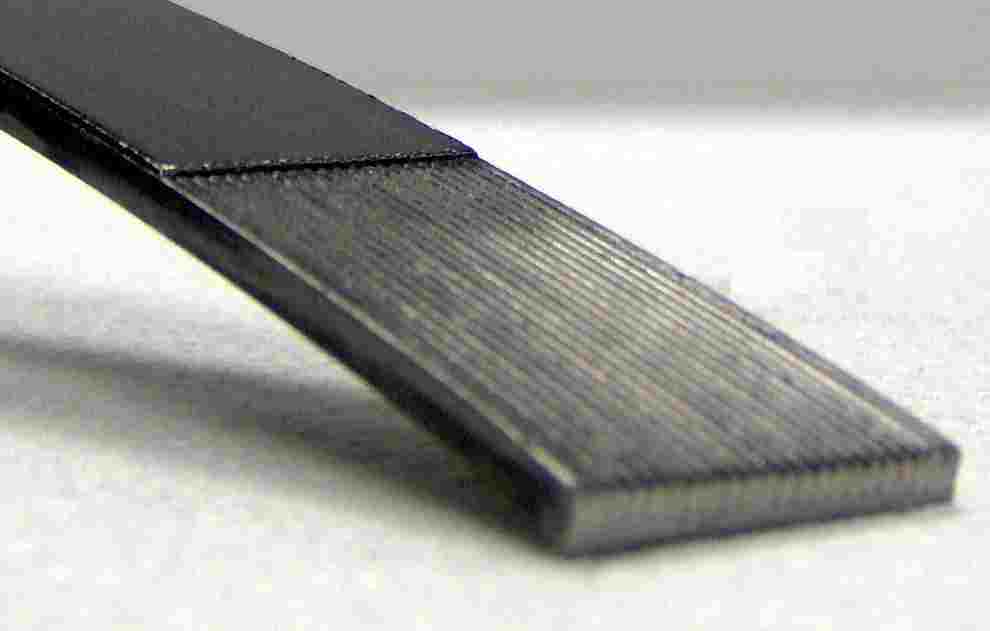

Camprofile Gaskets

Camprofile or "Grooved" Gaskets have proven themselves in all industrial applications. Camprofile gaskets are found in industrial power plants and in the primary circuits in nuclear installations. Used either between flanges or in heat exchanger units in nuclear applications. The Petrochemical and Chemical industries benefit too, as the gaskets are used in applications where high pressures and temperatures are maintained and consequently high bolt loads need to be controlled.

For flange protection the Camprofile gaskets are normally used in conjunction with a covering layer of either PTFE, Graphite etc, and provided that the layer thickness is correct in application the flange will be completely protected from the grooved profile of the gasket.

Advantages

- Outstanding sealing characteristics at a wide range of seating stress levels. Helps compensate for wide swings in temperature and pressure.

- Very forgiving of inconsistent bolt torqueing or installation error. Applicable to almost all types of flanges regardless of bolt load available.

- The working thickness of sealing layers is extremely small reducing fugitive emissions.

- Low seating stresses required reduce flange damage and gasket removal problems.

- The gasket cores are reusable reducing cost and eliminating gasket disposal problems.

- Offers extreme temperature and chemical resistance because of the variety of materials available.

- Extremely high pressure are easily sealed with confidence.

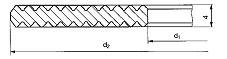

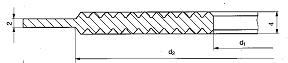

Camprofile Gaskets-for flanged joints

Example A without centering ring

Example B with centering ring

Seating stress at 70°F:

- Flexible Graphite PTFE

- Minimum: 2,900 lb/sq in. 2,900 lb/sq in.

- Recommended: 13,000 lb/sq in. 13,000 lb/sq in.

- Maximum: 58,000 lb/sq in. 58,000 lb/sq in.

Metals Available:

- 304 Nickel 200

- 304L Monel 400

- 316 Inconel 600

- 316L Hasteloy C

- 316TI Hastelloy B2

- 321 Titanium

- 347 Copper

- Aluminum

- (other on request)

Note: Metal selection is usually consistent with piping system.

Sealing Elements Available:

- Flexible Graphite

- Teflon®

|