|

| |

|

|

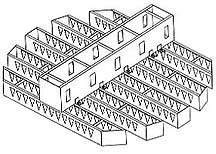

Liquid Distributor

This is a typical liquid distributor with single parting box and weir troughs. Liquid loading, gas loading and column diameter will dictate the number of parting boxes and wier troughs. Construction is such that pressure drop is minimized- normally .25" WC or less.

All Lantec liquid distributors are designed to be supported from a circumferential ring supplied as an integral part of the column. Distributor furnished in sections, suitable for installation through manway of specified dimension (normally 24"). Assembly hardware included. |

|

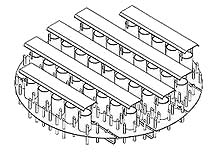

Liquid Distributor

This is a typical liquid distributor designed to provide excellent water distribution over a wide turn down ratio. Note the multiple risers, orifices and drip tubes assuring gas and liquid separation hence minimum pressure drop: .25" WC or less.

Construction permits installation through manway of specified dimension (normally 24"). Hardware, leveling clamps and gasketing included. |

|

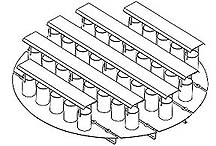

Collector Distributor

Used when multiple packing sections are incorporated in the column design. Risers are generous in cross section and adequately covered preventing the entrance of water assuring a free flow of air. Pressure drop is minimized: .35" WC or less. |

|

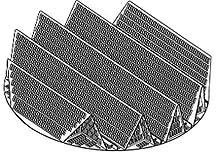

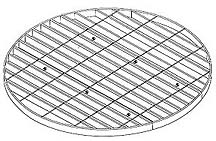

Multi Beam Gas Injected (MBGI) Packing Support

This design offers almost 100% open area hence minimizing pressure drop: .1/.15" WC.

MBGI packing support construction allows installation through manway- manway size to be specified (normally 24"). All necesary assembly hardware including leveling clamps provided.

MBGI supported by circumferential ring furnished as an integral part of the column. MBGI is normally self supporting. Lantec will advise the need of any additional support beams. |

|

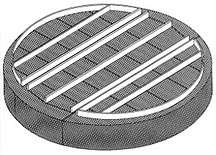

Simple Grid Support with an open area of 75-80%. Pressure drop estimated at .45" WC.

Design permits installation through manway, size to be specified by column designer, normally 24". All necessary assembly hardware included.

Grid supported by circumferential ring furnished as integral part of the column.

Grid may be self supporting. Lantec will advise if addional support beams are required. |

|

Pad Mist Eliminator

Has support grids at the top and bottom. Pad mist eliminator applications require special consideration to assure the removal of entrained moisture in the effluent gas stream. |

Catalog:

1. Inert Ceramic Ball as Catalyst Support Media(Equivalent to Donstone Series)

2. Ceramic Random Packing:

(1). Ceramic Pall Ring

(2). Ceramic Raschig Ring

(3). Ceramic Cross-Partition Ring

(4). Ceramic Intalox Saddle Ring

(5). Ceramic Supper Intalox Saddles

(6). Ceramic Cascade-mini Ring

3. Metal Random Packing:

(1). Metal Pall Ring

(2). Metal Raschig Ring

(3). Metal Intalox Ring(Equivalent to IMTP)

(4). Metal Nutter Ring

(5). Metal VSP Ring

(6). Metal Cascade-mini Ring

(7). Metal Conjugate Ring

P. S. Metal availabe in Materials: S. S. 302, 304, 316, 316L, 317, 317L, carbon steel, aluminum, alloy, etc.

4. Plastic Random Packing:

(1). Plastic Pall Ring

(2). Plastic Rosette Ring

(3). Plastic Super Intalox Ring

(4). Plastic Cascade Mini Ring

(5). Plastic Saddle Ring

(6). Plastic Heilex Ring

(7). Plastic Conjugate Ring

(8). Polyhedral Hollow Ball

P. S. Plastic Series availabe in Materials: PP, PVC, CPVC, PVDF etc.

5. Metal structured packing

(1). Perforated & corrugated plate

(2). Corrugated plate gauze

(3). Pricked & corrugated plate

(4). Corrugated wire gauze and

(5). Annular corrugated plate

6. Molecular Sieves

(1). Molecular Sieve type 3A

(2). Molecular Sieve type 4A

(3). Molecular Sieve type 5A

(4). Molecular Sieve type 13x |

|

|

| Pall ring | Tellerette ring | IMTP ring | Ceramic Alumina ball | PTFE expansion joint | Rubber expansion | Liquid distributor |

|