High performance liquid distributors aim towards ideal liquid distribution, i.e. equal liquid rate per unit area of the packed bed surface. These distributors are available in a complete range to suit various column diameters, liquid rates and service conditions. Models, which can give turndown ratio upto 10:1, are available. Our design team selects the most suitable model for a given application. High performance liquid distributors aim towards ideal liquid distribution, i.e. equal liquid rate per unit area of the packed bed surface. These distributors are available in a complete range to suit various column diameters, liquid rates and service conditions. Models, which can give turndown ratio upto 10:1, are available. Our design team selects the most suitable model for a given application.

|

| |

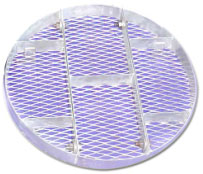

| Bed Limiter |

Bed limiters are safety devices that are available for both random as well structured packing to avoid the expansion of the packed bed, as well as to maintain the bed top surface level.

Bed limiters are safety devices that are available for both random as well structured packing to avoid the expansion of the packed bed, as well as to maintain the bed top surface level. |

| |

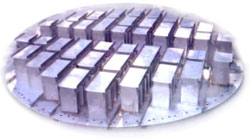

| Support Plate |

Support plates in addition to providing physical support to the packings, must also allow unrestricted flow of gas and liquid. Gas injection support plates provide separate passageways for liquid and gas, which minimizes the pressure drop across the plate. Support plate model is selected depending upon the packing type and size and the maximum design load to be supported.

Support plates in addition to providing physical support to the packings, must also allow unrestricted flow of gas and liquid. Gas injection support plates provide separate passageways for liquid and gas, which minimizes the pressure drop across the plate. Support plate model is selected depending upon the packing type and size and the maximum design load to be supported. |

| |

| Collector/Chimney Tray |

Collector trays are used to collect liquid from between packed beds. Liquid interception is required in various situations such as total or partial draw-off of liquid, change in the column diameter, which sometimes necessitates the redistribution of the liquid; to cool the liquid in absorbers before passing to the next packed bed etc. Different types of collector trays are available to suit the column diameter and the vapour and liquid rates.

Collector trays are used to collect liquid from between packed beds. Liquid interception is required in various situations such as total or partial draw-off of liquid, change in the column diameter, which sometimes necessitates the redistribution of the liquid; to cool the liquid in absorbers before passing to the next packed bed etc. Different types of collector trays are available to suit the column diameter and the vapour and liquid rates. |

| |

| Feed Device |

Different feed devices are available for various feed conditions of the fluid entering the column such as only liquid feed, mixed feed or gaseous feed. Feed devices are selected to complement with the type of distributor used to give the optimum performance of each.

Different feed devices are available for various feed conditions of the fluid entering the column such as only liquid feed, mixed feed or gaseous feed. Feed devices are selected to complement with the type of distributor used to give the optimum performance of each. |

| |

| Pall ring | Tellerette ring | IMTP ring | Ceramic Alumina ball | PTFE expansion joint | Rubber expansion | Liquid distributor |