|

| |

|

| Bellows Capsules |

T.C.I designs bellows capsules according to the Expansion Joint Manufacturer's Association (EJMA) guidelines. We supply qualified fabricators pre-engineered bellows, flow liners and vanstone stub ends to meet their individual requirements. Our strict manufacturing processes and quality control procedures insure a precise product every time. T.C.I designs bellows capsules according to the Expansion Joint Manufacturer's Association (EJMA) guidelines. We supply qualified fabricators pre-engineered bellows, flow liners and vanstone stub ends to meet their individual requirements. Our strict manufacturing processes and quality control procedures insure a precise product every time.

Single ply and multi ply bellows are available in sizes 1-1/2" through 104" diameter. Metal bellows can be made in most alloys.

TCI uses T-321 stainless steel as a standard due to its excellent forming properties and high temperature properties. Other common alloys stocked at TCI include T-316 and T-304 stainless steel, Inconel 625, Monel 400 and Hastelloy C276.

|

|

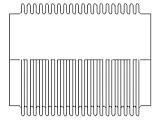

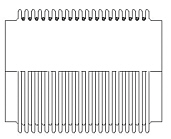

A single thickness of material is used to form the bellows. The necks or tangents can be sized to fit the customer's fittings. Each bellow's application is engineered for maximum performance

|

|

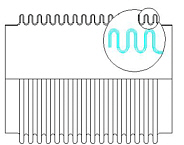

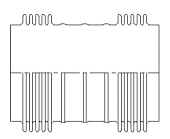

Multiple layers of material are used to form this bellows. The benefits are lower spring forces, higher cycle life and can be used to dampen equipment vibration.

|

|

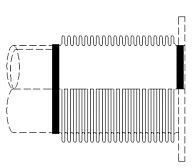

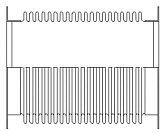

Bands are used to reinforce the bellows necks due to pressure considerations or to make welding easier. The internal or external bands are expanded with the bellows neck to size. The customer welds the band and neck to their fittings.

|

|

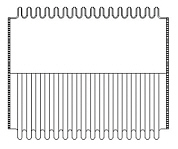

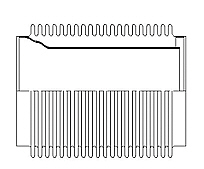

For ease of fabrication, the layers of material on multi-ply bellows can be resistance welded together at the necks.

|

|

Applications for very high pressures may require the valley and sidewall of the convolution to be supported. One method is the use of external reinforcing "Root Rings".

|

|

This unique bellows is used for low-pressure applications that require lateral movement. The center spool requires no welding and uses dimples to maintain rigidity. Standard universal construction must be used if flow liners are required.

|

|

Single ply or multi-ply bellows can be shipped with vanstone stub ends sized and fit to the necks, but not welded. The customer can insert his own floating flanges then reassemble and weld.

|

|

When a flow liner is required, DME can furnish one fit directly to the bellows neck. This eliminates the need for a separate liner attachment weld. |

|

|

|

| Pall ring | Tellerette ring | IMTP ring | Ceramic Alumina ball | PTFE expansion joint | Rubber expansion | Liquid distributor |

|