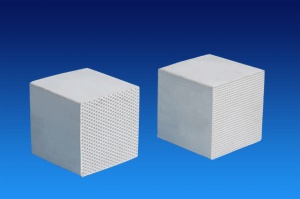

Honeycomb Ceramic

Honeycomb Ceramic is porous ceramic with parallel channels triangular, square and hexagonal internals. The honeycomb units are separated by thin walls, the materials are mainly Cordierite(2MgO.2Al2O3.5SiO2), Aluminium Titanate(Al2TiO5), Mullite (3Al2O3.2SiO2), Corundum(α-Al2O3) and compound phases, etc.

Compared with general ceramics, the materials have characteristics as: low thermal expansion, high heat shock resistance, anti-oxidation, large specific surface area and corrosion-resistance, etc. Honeycomb Ceramic is mainly used in metallurgy, tower packing in chemical industry, construction, heat-regenerative and high-temperature air purification, industrial waste gas treatment, NOx purified system in firepower plant, purified system for?harmful?gas?rising?from?refuse?burning, and?noxious?gas purification in chemical and mining industries, acting as filter and catalyst carrier used in founding process.

Honeycomb Ceramic for HTAC

Honeycomb Ceramic is porosity ceramic with parallel holes shaped as triangle, square or hexagon. The honeycomb units are separated by thin wall and they are used in the industry extensively.Currently the materials for products are mainly,Cordierit (2MgO.2Al2O3.5SiO2Mullite (3Al2O3.2SiO2),Corundum(α-Al2O3) and compound phases, etc.

Compared with general ceramics, the materials have characteristics as: low thermal expansion, high heat impact resistance, anti-oxidation, large specific surface area and corrosion-resistance,etc.This product is mainly used in metallurgy,tower packing in chemical industry, construction, heat-regenerative and high-temperature air purification, industrial waste gas treatment, NOx purified system in firepower plant, purified system for harmful gas rising from rubbish burning,and poisonous gaspurification in chemical and mining industries, acting as filter and catalyst carrier used in foundry process.

High Temperature Air Combustion (HTAC) is a revolutionary combustion system, which achieves the outstanding fuel saving by high preheated air combustion and high efficiency waste heat recovery.

Honeycomb ceramic with more characteristics such as high surface area, high heat transfer ability, strong thermal shock resistance, high operating temperature, anti-iron oxide skin erosion, effective in reducing the size and weight of regenerative boxes. It can achieve low NOx emission more than 40%.

Chemical analysis |

Composition |

Value (%) |

SiO2 |

16-20 |

Al2O3 |

72-77 |

MgO |

<1 |

Fe2O3 |

<1.5 |

TiO2 |

<4 |

K2O+Na2O+CaO |

2-3 |

|

|

|

Physical properties |

No |

Index |

Unit |

Value |

1 |

Gross Density |

g/cm3 |

2.3~2.6 |

2 |

Average Linear Expansion(20-1000℃) |

10-6/k-1 |

6-7.6 |

3 |

Specific Heat Capacity |

KJ/Kg |

900~1200 |

4 |

Heat Conductivity |

W/MK |

1.8~3 |

5 |

Soft Temp. |

℃ |

1400 |

6 |

Maximum Application Temp. |

℃ |

1350 |

7 |

Corrosion Resistance Against Acid |

% |

99.5 |

|

Dimension and other physical properties |

Dimension |

Quantity

of

channels |

Wall

thickness

(mm) |

Channel

Width

(mm) |

Surface

area

(m2/m3) |

Void section (%) |

Packaging density

(kg/ m3) |

Weight per piece (kg) |

150×150×300 |

25×25 |

1.0 |

4.96 |

580 |

68 |

696 |

4.7 |

150×150×300 |

32×32 |

1.0 |

3.66 |

695 |

61 |

755 |

5.1 |

150×150×300 |

40×40 |

0.7 |

3.03 |

891 |

65 |

814 |

5.5 |

150×150×300 |

43×43 |

0.7 |

2.77 |

940 |

63 |

858 |

5.8 |

150×150×300 |

50×50 |

0.6 |

2.39 |

1090 |

63 |

903 |

6.1 |

150×150×300 |

60×60 |

0.5 |

1.99 |

1303 |

63 |

932 |

6.3 |

|

|