Plastic tower packings are made of those heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene(RPP), polyvinyl chloride(PVC), chloridized polyvinyl chloride(CPVC) and polyvinylidene fluoride (PVDF). Them are feature such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency and so on, and the application temperature in media ranges from 60to 150. For these reasons them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc. Plastic tower packings are made of those heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene(RPP), polyvinyl chloride(PVC), chloridized polyvinyl chloride(CPVC) and polyvinylidene fluoride (PVDF). Them are feature such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency and so on, and the application temperature in media ranges from 60to 150. For these reasons them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

|

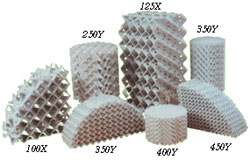

| Ceramic Structured Packing |

Ceramic surface can generate extremely thin liquid film. Turbulent liquid flow and tortuous vapor flow passages promote mixing of liquid and vapor with low pressure drop. These are reasons that our ceramic structured packings have the same mass transfer efficiency as metal packings. Meanwhile, they are much more resistant to corrosion and high temperature than metal packings. The surface structure of ceramic packing could promote its wetting and keep liquid hold-up to a minimum. So chance for the system to be overheated, polymerized and coked could be minimized.

Ceramic surface can generate extremely thin liquid film. Turbulent liquid flow and tortuous vapor flow passages promote mixing of liquid and vapor with low pressure drop. These are reasons that our ceramic structured packings have the same mass transfer efficiency as metal packings. Meanwhile, they are much more resistant to corrosion and high temperature than metal packings. The surface structure of ceramic packing could promote its wetting and keep liquid hold-up to a minimum. So chance for the system to be overheated, polymerized and coked could be minimized. |

| |

| Excellent Features |

1) High liquid & vapor loading. Column I.D. could be designed smaller for new equipment and capacity could be

1) increased remarkably for existing column revamp.

2) High mass transfer efficiency. Much higher specific surface area than random packings.

3) Low pressure drop, and considerable energy savings.

4) Wide turndown ratio. Easy to scale up.

5) Suitable for all sizes of columns.

6) High resistance to acids and alkalis, especially to H2S, naphthenic acids and chlorides. |

| |

| Physical Characters |

| |

Density g/cm3 |

Moisture Absorbency % |

Heat-Resistant |

Pressure Resistant MPa |

2.5 |

<0.5 |

800 |

>130 |

|

| |

| Geometrical Character of Packings |

| |

Type |

Void % |

Thickness mm |

Density

Kg/m3 |

Crimp Height mm |

Crimp Distance mm |

Gear-Shape Angle |

F-Factor m/s (Kg/m3 )1/2 |

450Y |

76 |

1.2 0.2 |

552 |

6 |

11 |

80 |

1.5-2 |

350Y |

80 |

1.2 0.2 |

490 |

9 |

15 |

80 |

2 |

250Y |

82 |

1.40.2 |

450 |

13 |

22 |

80 |

2.5 |

125Y |

85 |

2.50.5 |

370 |

23 |

42 |

80 |

3 |

100Y |

87.5 |

2.50.5 |

300 |

30 |

50 |

80 |

3.5 |

|

| |

| ?Applications |

1)Distillations and Absorption of strong corrosive mixtures;

2)Distillation of halogenated organic components;

3)Used as heat-exchanger, catalyst support. |

| |

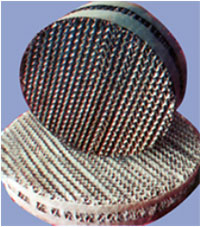

| Metal Plate Netted Corrugated Packing |

Usage: Usage:

1)Rectification of halogen organic chemicals;

2)Rectification, absorption process with high demand to pressure loss and theoreticalplates;

3)acid medium tower;

4)The vacuum operation of 100Pa to normal pressure;

5)Catalyst carrier for heat exchanger & mist eliminator.

|

| |

Size |

peak value

H |

Surface contrast

m2/m3 |

hydraulic

diameter

ahmm |

slant angle a |

voidage

% |

F Gene

m/s |

Layers

no/m |

Pressure drop

mmHg/m |

CY |

4.3 |

700 |

5 |

45 o |

87-90 |

1.3-2.4 |

6-9 |

5 |

BX |

6.3 |

500 |

7.3 |

30 o |

95 |

2-2.4 |

4-5 |

1.5 |

|

| Pall ring | Tellerette ring | IMTP ring | Ceramic Alumina ball | PTFE expansion joint | Rubber expansion | Liquid distributor |