|

ss304, SS316 SIEVE TRAYS

- SIEVE, VALVE, DUAL FLOW, BUBBLE CAP AND CARTRIDGE TRAYS.

- PACKED TOWER INTERNALS AND RANDOM AND STRUCTURED PACKINGS.

- WIRE MESH DEMISTERS AND VANE TYPE MIST ELIMINATORS.

- FABRICATE REACTOR AND OTHER SPECIALLY DESIGNED INTERNALS.

- RE-DESIGN AND FABRICATION OF OLD TRAYS AND INTERNALS TO IMPROVE HYDRAULIC AND MECHANICAL PERFORMANCES INCLUDING TRUNCATED DOWNCOMER FOR TRAYS.

- PROVIDE SUPERVISION, DEMOLITION AND INSTALLATION SERVICES.

TYPE OF TRAYS

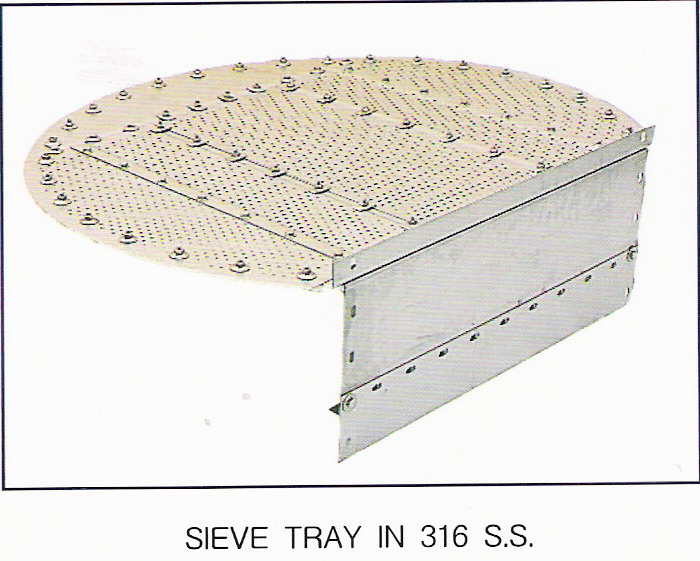

SIEVE TRAY IN 316 S.S.

TRAY CONSTRUCTION MATERIALS

Fractionation trays are fabricated from a wide variety of materials. When corrosion is expected to be extremely low and design temperatures are not excessive, carbon steel is a logical choice because of it favorable mechanical design properties, malleability and low cost. However, since the material of construction is dictated by the process of each particular system for which the tray will be used, many different material types may be required because of unique properties which allow some materials to have resistance to corrosion and to maintain their mechanical strength at elevated temperatures.

The most common tray materials that HMT utilizes are listed below starting from least expensive :

| - Carbon |

- Type 410s stainless steel |

| - Type 304 Stainless steel |

- Type 316 Stainless steel |

Other fairly common material for tray fabrication are as follows :

| - Type 304L stainless |

- Type 316L stainless steel |

| - Type 317 stainless |

- Type 317L stainless steel |

| - Type 321 stainless |

- Type 347 stainless steel |

| - Type 904L stainless |

- Type 254 SMO |

HMT has experiences and skills at tray fabrication, utilizing many of materials below such as :

| - Titanium |

- Nickel |

- Polypropylene |

| - Zirconium |

- AL-6XN |

- Polyethylene |

| - Hastelloy |

- Everdur |

- C-pvc |

| - Monel |

- Copper |

- Teflon |

| - Inconel |

- Aluminum |

- F.R.P |

|