These valve-type trays have replaced bubble cap and sieve trays as the industry standard. FLEXITRAY® and BALLAST® valve trays have a higher efficiency over a broader range of operating conditions than sieve trays and can handle liquid loadings up to 10% greater than other tray types. Other advantages include low cost, simple installation, low pressure drop, excellent turndown, and reduced maintenance. These trays have demonstrated superior performance in more than 15,000 installations.

FLEXITRAY® Valve Trays combine high capacity and excellent efficiency with a wide operating range. With these product advantages plus Koch-Glitsch technical expertise in design, manufacturing, and installation, it's no wonder Koch-Glitsch valve trays have been installed in so many plants worldwide. Year after year, they continue to be the trays preferred by plant operators.

Uniform vapor distribution, wide operating range.

FLEXITRAY® Valve Trays are perforated sheet metal decks on which round, liftable valves are mounted. The vapor flows through alternating rows of valves which are installed parallel to the outlet weir.

FLEXITRAY® Valve Trays provide excellent liquid/vapor contacting for high efficiency, permit reduction of the reflux ratio for a given tower diameter, or allow a smaller tower diameter for a given feed rate. The vapor exiting a valve is directed horizontally, rather than vertically as in a sieve tray, reducing entrainment. This also allows longer run times in fouling services because horizontal radial vapor flow at the tray floor reduces "dead spots" where solids can settle, polymer growth can start, or decomposition can occur.

Higher capacity, low pressure drop

FLEXITRAY® Valve Trays can handle loadings up to 10% higher than sieve trays while providing higher efficiency. The contoured hole of the To type valve provides the lowest pressure drop per tray over a wide range of flow rates.

Cost-Effective

Initial purchase price, simple installation, and reduced maintenance contribute to cost effective projects when using FLEXITRAY® Valve Trays.

Versatility

An existing tower equipped with FLEXITRAY® Valve Trays can often be used in a different application with minimum modifications due to the trays' wide operating range, high capacity, low pressure drop, and excellent efficiency.

Versatile Valve Trays for Every Application

Koch-Glitsch has the valve type for your service.

The A, To and T valves can be supplied either with a flat periphery for tightest shutoff against liquid weepage at turndown rates or with a three-dimpled periphery to minimize contact with the tray deck for fouling or corrosive conditions.

A Standard valve with integral legs used for most services, utilizing a sharp-edged orifice in the tray floor; equivalent to Ballast® unit V-1.

T Round valve retained by a fixed holddown with a sharp-edged hole in the tray floor for all services including fouling, slurry, and corrosive applications.

To The same as T valve with a contoured, low-pressure drop hole in the tray floor.

Other trays:

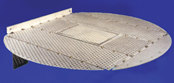

Sieve Tray

is a perforated tray with typically 8% to 15% open area, normally using 12.7mm-diameter holes.

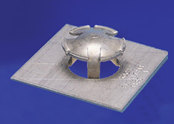

Chimney Tray

has risers and hats for vapor flow while collecting liquid for drawoff.

Bubble Cap Tray

has risers and fixed caps through which vapor flows and contacts the liquid on the tray.

Post-supported Tray

is used in small diameter towers typically less than 760 mm ?where trays are assembled one at a time over posts, or in cartridge bundles.

Shed Rows

are contacting devices for very heavily fouling service such as coker or cat unit slurry zones.

Other trays:

Sieve Tray

is a perforated tray with typically 8% to 15% open area, normally using 12.7mm-diameter holes.

Chimney Tray

has risers and hats for vapor flow while collecting liquid for drawoff.

Bubble Cap Tray

has risers and fixed caps through which vapor flows and contacts the liquid on the tray.

Post-supported Tray

is used in small diameter towers typically less than 760 mm ?where trays are assembled one at a time over posts, or in cartridge bundles.

Shed Rows

are contacting devices for very heavily fouling service such as coker or cat unit slurry zones.

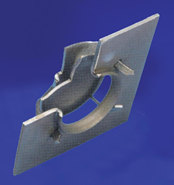

Caged

Valve

Trays

T.C.I specializes in the manufacturing of all types of Reactor Trays. Regardless of the OEM, we can manufacture most kinds of trays in any type of metallurgy from Carbon Steel to Hastelloy B-3, without sacrificing reliability or quality. Along with our wide variety of tray replacement options,

Round

Valves

Trays

we also offer fast and reliable emergency tray replacement through our centrally located Dallas plant. Even if your replacement needs only call for a manway panel or downcomer piece

Rectangular

Valve

Trays

you can be certain that T.C.I will be there to get the job done. So when you need it now, we will provide you with the service and quality you expect.

|