|

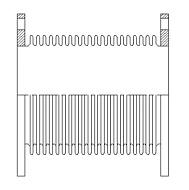

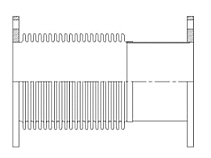

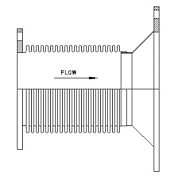

Fixed Flanged Exhaust Bellows |

Flanges are welded rigid on both sides. 1/2" thick plate flanges are most common for exhaust and blower applications. Stainless and carbon steel flanges can be fabricated with any bolt pattern in any size.

|

|

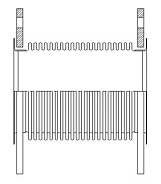

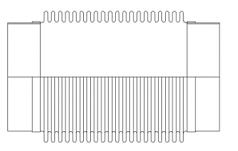

Vanstone Flange Exhaust Bellows |

Floating flanges or vanstone flanges eliminate bolt alignment problems. DME fabricates vanstone stub ends in stainless and other alloy materials. Carbon steel back up flanges are an economic solution.

|

|

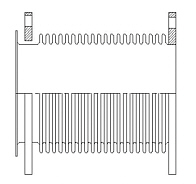

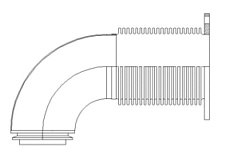

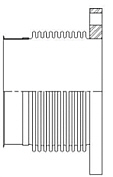

Fixed Flange Integral Floating |

A unique process allows us to form a vanstone end integral with the bellows. This eliminates a weld on one end. The fixed flange is generally an ANSI flange and the floating flange a Caterpillar, Detroit, Cummins, etc. |

|

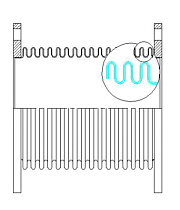

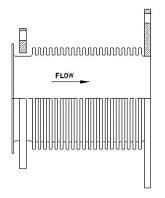

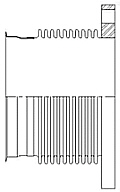

Multi-ply Flanged Bellows |

By design these joints have very low spring rates. On engine manifold applications, multi-ply expansion joints can absorb and isolate vibration and at the same time absorb certain amounts of thermal expansion. For critical applications such as marine and co-generation, multi-ply joints are a must.

|

|

The bellows length is generally limited to 12" in length. When a longer assembly is required, fabricated stainless steel tubes are used. For standby applications, carbon steel tubes are available. |

|

This assembly clamps directly to the turbo charger. Multi-ply bellows have very low spring forces and will protect the turbo from the piping stresses. Assemblies can be furnished with any outlet fitting required. |

|

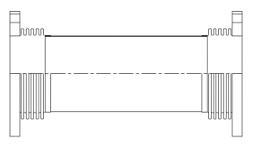

Multi-ply Universal Flanged |

Universal expansion joints allow for large amounts of lateral offset that can be created by thermal expansion of the piping or misalignment. By design the multi-ply construction will absorb and isolate engine vibration. |

|

Flanged with Reducing Flange |

Reducing flanges are used at the outlet side of the expansion joint to increase the flange size. This is an economical method to make a transition in size. |

|

Flanged with Tapered Transition |

Tapered cones are also used to make an increase or reduction in pipe size. When making a reduction, the cone creates a smooth flow thus minimizing the back pressure. |

|

Tube ends can be furnished in any length to accommodate the installation. Customers can easily weld their own flanges or fittings to the tube ends. DME has tube-making equipment that allows us to furnish ends in any size, thickness or alloy. |

|

Waukesha Lip Flange Bellows |

Whether your requirement is a replacement for a factory expansion joint or one custom made to your exact length, DME can help. 5" through 14" sizes are available with floating flanges and flow liners. |

|

Detroit Diesel, Cummins and John Deere lip flanges are available on single ply and multi-ply bellows. DME furnishes flared tubes in carbon and stainless steel. |

|

Beveled Weld End Exhaust Bellows |

Schedule 10, schedule 40 or heavy wall pipe ends can be furnished in any length.

37-1/2 degree bevels are provided to facilitate welding. If bevels are not required. Machined square cut ends are supplied.

|

|

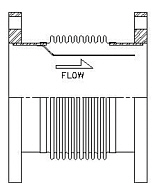

Flanged With Spacers and Liner |

Flange spacers are furnished in T-321 stainless steel. Expansion Joints can economically be furnished in any length. When a flow liner is required, spacer tubes prevent contact damage to the bellows. |