|

|

|

| |

|

Characteristics of structured packing

|

Name

|

Material

|

Nominal size

|

Surface area

|

Void

|

Packing factor

|

|

Flexipac

|

S

|

1”

|

558

|

91

|

108

|

|

S

|

2”

|

223

|

93

|

72

|

|

S

|

3”

|

134

|

96

|

52

|

|

Intalox

|

S

|

1T

|

315

|

95

|

66

|

|

S

|

2T

|

213

|

97

|

56

|

|

Max-pak

|

S

|

|

229

|

95

|

39

|

|

Mellapak

|

S

|

125Y

|

125

|

97

|

33

|

|

S

|

125X

|

125

|

97

|

|

|

S

|

250Y

|

250

|

95

|

66

|

|

S

|

250X

|

250

|

95

|

|

|

S

|

350Y

|

350

|

93

|

75

|

|

S

|

500X

|

500

|

91

|

25

|

|

Sulzer

|

G

|

AX

|

250

|

95

|

|

|

G

|

BX

|

492

|

90

|

69

|

|

G

|

CY

|

700

|

85

|

|

|

Montz-pak

|

S

|

B1-125

|

125

|

97

|

|

|

S

|

B1-125.6

|

125

|

97

|

72

|

|

S

|

B1-250

|

250

|

95

|

|

|

S

|

B1-250.6

|

250

|

95

|

|

|

S

|

B1-350

|

350

|

93

|

|

|

G

|

A3-500

|

500

|

91

|

|

|

E

|

BSH-250

|

250

|

95

|

|

|

E

|

BSH-500

|

500

|

91

|

|

|

Ralupac

|

S

|

250YC*250

|

|

95

|

|

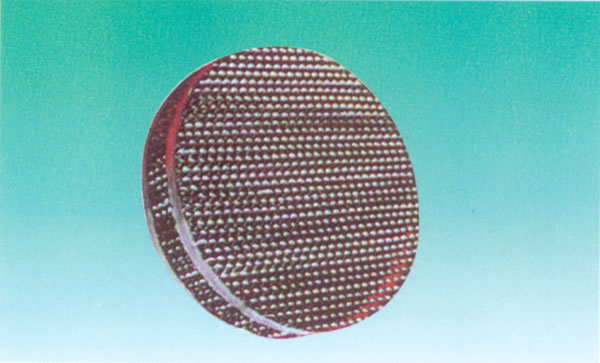

Metallic structure tower packing, Metal Mesh Ripple Packing is made of plate-shaped ripple regular packing consist of given pressing extended

mesh sheet punched and extended by metal sheet board with regular rhombic mesh on the surface, keeping

geometric regular structure of silkscreen ripple packing for pressing to ripple sheet. It can be divided

into two models WS-45 and WS-30 according to inclined angle between peak height of ripple and tower axis. |

Geometric Characteristic Parameters

Metallic structure tower packing

|

Model

|

Inclined Angle (Degree)

|

Theoretical Board Number No/m

|

Peak Height(mm)

|

Hydraulic Diameter(mm)

|

Rate of Surface Area/Volume (m2/m3)

|

Interstitial Rate (%)

|

|

WS-45

|

45

|

6-8

|

4.5

|

5.7

|

600

|

91.6

|

|

WS-30

|

30

|

4-5

|

6.5

|

9

|

450

|

95.5

|

|

|

|

| New Product |

|

Polypropylene Tellerette 3K

ETFE +25% Glass Tri packs 2inch

|

| |

|

|

|

|

| |

|

|

|

|

|