|

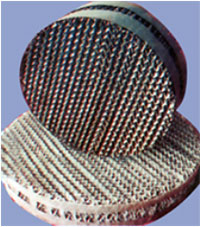

Corrugated Structured Packing

Corrugated structured packing is constructed of sheets of corrugated metal or plastic. The angle of inclination of the corrugations of adjacent sheets is reversed with respect to the vertical column axis, forming mixing cells at every point where the corrugations intersect. Perforations and surface texturing, including waffled, grooved and smooth, promote intimate mixing and radial distribution over the entire tower cross-section. Each subsequent element is rotated 90?about the column axis so that the sheets of one element are perpendicular to the sheets of the elements above and below. In passing through each element, gas and liquid are thoroughly mixed in the direction parallel to the plane of the sheets. By rotating subsequent elements, excellent mixing and spreading, both side-to-side and front-to-back, are obtained over the entire cross-section of the tower. Corrugated structured packing operates over a wide range of liquid and gas rates. With more than 10 types of Corrugated packing available, AceChemPack can provide the right products to meet your specific tower requirements.

Corrugated packing offers higher capacity and/or higher efficiency than random packing or conventional trays. Corrugated packing revamp can increase separation efficiency, increase capacity, lower pressure drop, and often significantly lower the energy costs of distillation and absorption operations. That means retrofitting existing packed or trayed towers with A Corrugated packing will improve profitability.

Application:

corrugated structured packing widely used in temperature sensitive application where large number of theoretical stages are needed. Low liquid loading systems for vacume distillations or organic intermediates, amines, glycols, fatty acids, essential oils and fragrances. Suitable for solvent recovery, batch & continuous distillation system. and system of ethylbenzene / benzene second, hexamethylene kelone/ hexamethylene mellow, oneself lactam. absorb or regeneration tower.

Materials: Stainless steel, 304L, 316L.carbon steel, aluminum, bronze etc

Properties:

|

Model

|

surface area

α

m 2 /m 3 |

void space

% ε m 3 /m 3 |

Waterpower Diameter

de

mm |

Declined angle degree

|

F-factor

m/s kg/m 3 |

Theoretical tower plate NO/m |

|

125 x/y

|

125 |

98.5 |

18 |

30/45

|

3 |

1-1.2 |

|

250 x/y

|

250 |

97 |

15.8 |

30/45

|

2.6 |

2-3 |

|

350 x/y

|

350 |

96 |

11.5 |

30/45

|

|

|

|

450 x/y

|

450 |

93 |

9 |

30/45

|

1.5 |

3-4 |

|

500 x/y

|

500 |

93 |

8 |

30/45

|

|

|

|