FLEXIPAC® Structured Packing

FLEXIPAC® and GEMPAK® structured packings provide high capacity, higher efficiency and lower pressure drop than any random packing and most trays available today. Revamping existing packed or trayed columns with structured packing from Koch-Glitsch will increase the operation capacity of the tower, lower the pressure drop, and lower the energy cost of the distillation or absorption operation. Our structured packing elements may be fabricated in a variety of metals and plastics, as well as in ceramic.

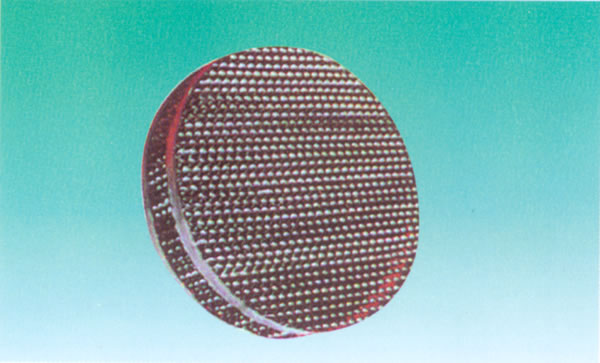

Koch-Glitsch gauze structured and GOODLOE® mesh structured packing are the most efficient commercial tower packing available today. Fabricated of a woven metal wire or plastic gauze, Koch-Glitsch gauze packing is well-suited for applications where low pressure drop is important and liquid rates are as low as 0.1 gpm/ft2. HETP is generally 5 - 8", regardless of column size. Pressure drop is as low as 0.2mm Hg per theoretical tray.

We can make this kind of structure packings in SS410, SS304, SS316 material etc.

and according to the following technical data.

| FLEXIPAC HC Structured Packing |

2Y |

250Y |

1.6Y |

1.4Y/350Y |

1Y |

500Y |

700 |

| Surface Area |

|

|

|

|

|

|

|

| ft2/ft3 |

68 |

77 |

90 |

106 |

129 |

152 |

220 |

| m2/m3 |

225 |

250 |

295 |

350 |

420 |

500 |

725 |

|