|

Ceramic structure tower packing

Tower Packings Of Ceramic

Ceramic tower packings have superior acid and heat resistance, can be resisted the acid corrosion and alkali except hydrofluoric. This product is applied to the drying tower, absorbing tower, cooling tower, desulphurization towers, rectifying tower, washing tower and regenerative tower, petrochemistry, chemical engineering, coal chemical engineering, fine chemical, fertilizer, sulphuric acid, smelting, electrical power and environmental protection industrie.

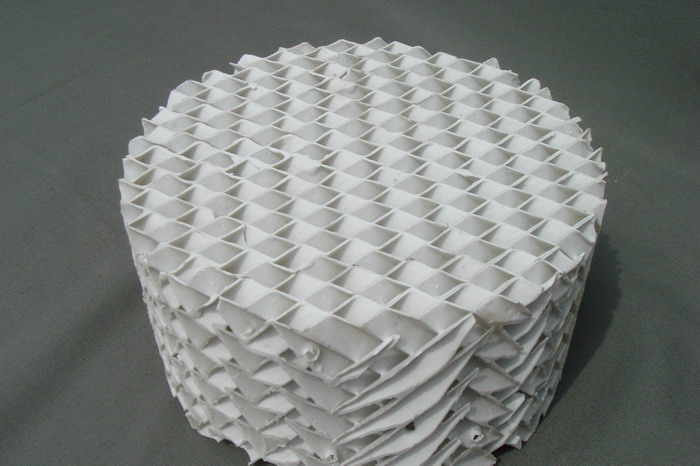

Structured Packings Of Ceramic

The ceramic structured packings are also called kelapak. It is composed of many packing units with the same geometric shapes. Each packing unit consists of parallel superposed corrugated sheets. Ceramic structured packing has high efficiency, low pressure drop, high capacity, scale effect is not obvious, high operating elasticity, corrosion resistance, heat resistance etc. It can widely used in the coal gas scrubbing tower、coking scrubbing benzene tower、scrubbing NH3 tower、fertilizer saturation-heat water column and scrubbing sulpher tower etc.

1.Technical data of ceramic structured packings:

|

Type

|

Specific surface area (m2/m3)

|

Void volume (m3/m3)

|

Hydraulic Diameter (mm)

|

Liquid Load (m3/m2.h)

|

The biggest F factor (m/s(kg/m3)0.5)

|

Pressure

Drop

(mmHg/m)

|

Theoretical

Plate(1/m)

|

Heaping Density

(kg/m3)

|

Obliquity

|

Wave crest hight(mn)

|

|

100X

|

100

|

92

|

30

|

0.2-100

|

3.5

|

1.5

|

1

|

280

|

30°

|

30

|

|

125Y

|

125

|

90

|

28

|

0.2-100

|

3.0

|

1.5

|

1.8

|

320

|

45°

|

23

|

|

125X

|

125

|

90

|

28

|

0.2-100

|

3.2

|

1.8

|

1.5

|

300

|

30°

|

23

|

|

150Y

|

150

|

85

|

15

|

0.2-100

|

2.8

|

1.8

|

2

|

370

|

45°

|

17

|

|

150X

|

150

|

85

|

15

|

0.2-100

|

3.0

|

2

|

1.8

|

350

|

30°

|

17

|

|

250Y

|

250

|

80

|

12

|

0.2-100

|

2.6

|

2

|

2.5

|

420

|

45°

|

13

|

|

250X

|

250

|

80

|

12

|

0.2-100

|

2.8

|

2.5

|

2.3

|

400

|

30°

|

13

|

|

350Y

|

350

|

78

|

10

|

0.2-100

|

2.5

|

2.5

|

2.8

|

470

|

45°

|

9

|

|

350X

|

350

|

78

|

10

|

0.2-100

|

2.6

|

3

|

2.5

|

450

|

30°

|

9

|

|

400Y

|

400

|

75

|

8

|

0.2-100

|

2.0

|

3

|

3

|

500

|

45°

|

7.5

|

|

400X

|

400

|

75

|

8

|

0.2-100

|

2.2

|

4

|

2.8

|

480

|

30°

|

7.5

|

|

450Y

|

450

|

72

|

7

|

0.2-100

|

1.8

|

4

|

4

|

520

|

45°

|

6

|

|

450X

|

450

|

72

|

7

|

0.2-100

|

2.0

|

4.5

|

3-4

|

500

|

30°

|

6

|

|

470X

|

470

|

75

|

7

|

0.2-100

|

1.8

|

5

|

5

|

540

|

30°

|

7

|

|

550X

|

550

|

74

|

6

|

0.18-100

|

1.3

|

5.5

|

6

|

620

|

30°

|

10

|

|

700X

|

700

|

72

|

5

|

0.15-100

|

1.4

|

6

|

5

|

650

|

30°

|

8

|

2.Physical properties of ceramic structured packings:

|

Heat resistance(°C)

|

Water absorption(%)

|

Acid resistance(%)

|

Alkali resistance(%)

|

Crush Strength (Mpa)

|

Hardness (Mohs)

|

|

1400

|

≤0.5

|

≥99.8

|

≥92

|

≥130

|

≥7

|

|